Size: 24 × 16 × 20 in

Roof-Access Ready

The whole system moves through standard roof access, so crews start lining jobs where others cannot even enter.

Compact power for tight spaces

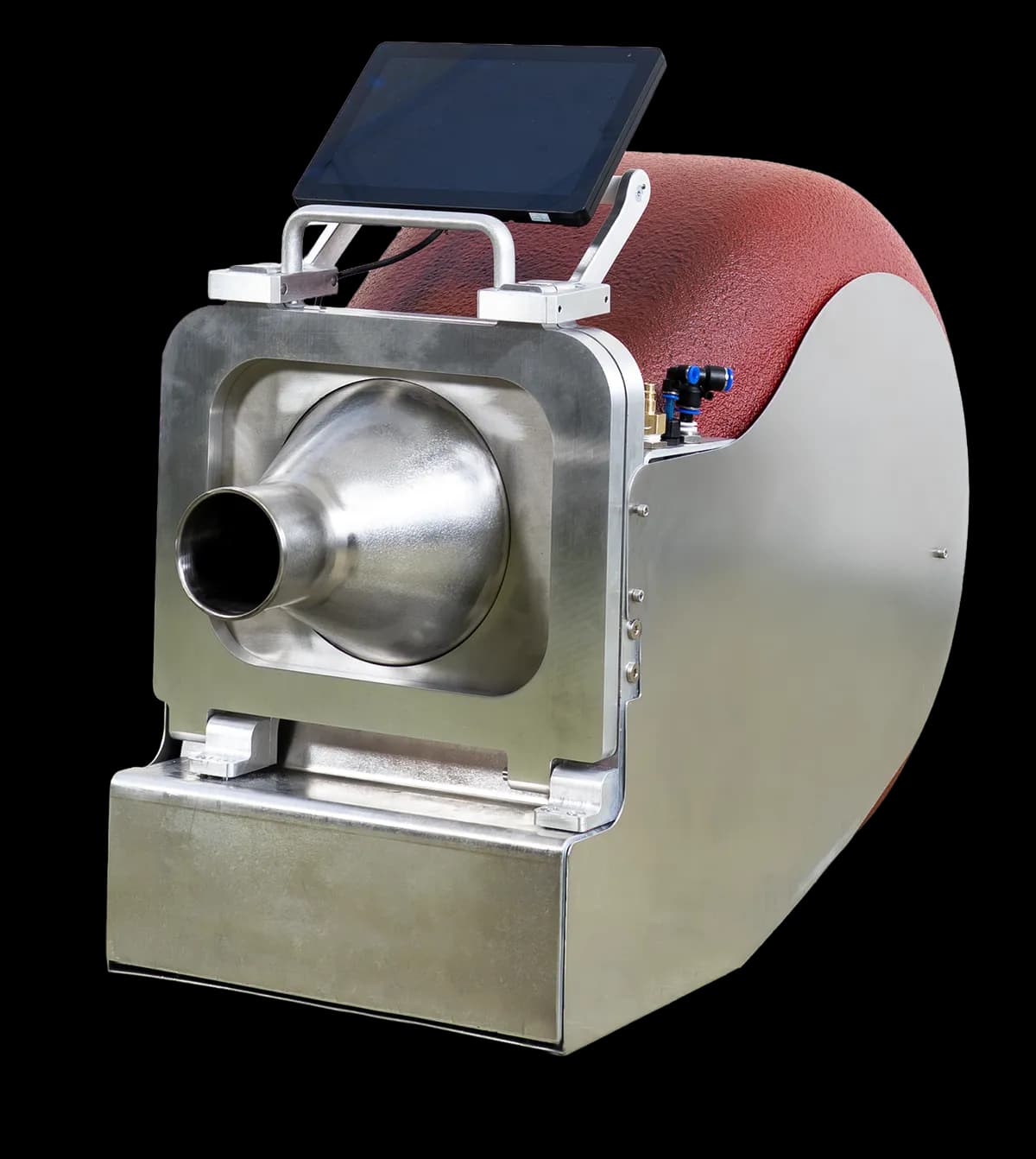

The Sewerbot Compact is our portable, high-performance UV curing solution designed for smaller diameter pipes and tight access situations. Perfect for residential and light commercial applications where space is at a premium.

How Sewerbot Compact Changes the Jobsite

Size: 24 × 16 × 20 in

The whole system moves through standard roof access, so crews start lining jobs where others cannot even enter.

AC input: 230V & 110V

Run with a compact compressor and a normal power outlet. No heavy truck setup, no overbuilt site logistics.

6 TOPS optimized AI capacity

Smart assistance handles the hard monitoring work, so operators stay in control and keep every step calm and predictable.

Uploads everything to Cloud

Curing data and job records sync back to the cloud, giving instant documentation for QA, reporting, and customer trust.

Overview

The Sewerbot Compact is our portable, high-performance UV curing solution designed for smaller diameter pipes and tight access situations. Perfect for residential and light commercial applications where space is at a premium.

STEP 01

STEP 01The whole system moves through standard roof access, so crews start lining jobs where others cannot even enter.

STEP 02

STEP 02Run with a compact compressor and a normal power outlet. No heavy truck setup, no overbuilt site logistics.

STEP 03

STEP 03Smart assistance handles the hard monitoring work, so operators stay in control and keep every step calm and predictable.

STEP 04

STEP 04Curing data and job records sync back to the cloud, giving instant documentation for QA, reporting, and customer trust.

Dual Camera feed

Features AI-driven automation for simplified, one-click control and real-time remote operation, with full manual control always available.

Over 1200 W adjustable power

Introducing our advanced UV head with over 1200 watts of adjustable power. Operating at a 395 nm wavelength, it is ideal for CIPP technologies.

Water consumption: 0.13 gal/min

The UV head's vapor cooling technology increases efficiency and reliability, particularly in harsh environments. Requiring less than 0.5 l/min waterflow, the efficient vapor cooling allows for a smaller, quieter air compressor, enhancing the system's performance and reducing noise.

Uploads everything to Cloud

Operational parameters and camera images are recorded for quality assurance, with all data uploaded to the cloud.

Features

10.1 Touchscreen display

For real-time procedure visualisation Sewerbot includes two cameras.

Drum Capacity

Combines lightweight design with durability, ready to operate with just a compressor and electrical power.

230V & 110V

Simplified operation with a standard 230V/110V compressor, eliminating the need for an air chiller and making on-site handling much easier.

Uploads everything to Cloud

Offers long-term efficiency with over-the-air updates that enhance functionality and superior connectivity.

Single-Access Relining

Relines pipes with a closed or inaccessible far end using a single entry point. Ideal for challenging locations. Also known as: Blind Shot.

Dual-Access Relining

Relines the entire length between two access points, providing comprehensive rehabilitation for full sections. Also known as: Manhole-to-Manhole.

Spot Repair

Targets small, localized damage with short linings (up to 2 m), delivering fast, budget-friendly fixes across the full DN70-DN300 range (optimized for DN100-DN200). Also known as: Patch Repair.

Junction Relining

Reinforces T-junctions and complex pipe configurations (optimized for DN100-DN200) to prevent leaks and root intrusion. Also known as: Top Hat or T-Connection.

This process leverages advanced technology to repair underground pipes without the need for disruptive excavation, ensuring a faster and more cost-effective solution for sewer rehabilitation.

Open the existing manhole or access point to begin the process without excavation.

Prepare the Ultrapreg liner, scanning the QR code for fluid data integration.

Scan the QR Code: Use a QR scanner to read the code on Ultrapreg. This automatically uploads all necessary data to Sewerbot, ensuring accurate application and documentation. So it makes your work much more easier!

Invert the prepreg: Load Ultrapreg into Sewerbot and push the start button. Sewerbot does the rest of it automaticly.

The machine is designed to handle a variety of liner sizes and lengths, making it versatile for different pipe diameters and rehabilitation requirements.

The integrated drum and UV head are engineered for compact and efficient operation. The AI-driven automation system simplifies the setup, reducing manual intervention and potential errors.

UV Light Curing: Sewerbot inverts the Ultrapreg liner into the pipe and positions it accurately. The powerful UV head, with over 1200 watts of adjustable power, then cures the resin. The UV curing ensures a quick and thorough hardening of the resin, forming a durable new pipe within the old one.

Real-Time Monitoring: The system includes cameras and sensors to monitor the curing process. This data is recorded and uploaded to the cloud for quality control and future reference.

Final Inspection: After curing, conduct a final inspection using Sewerbot's integrated camera system. This ensures the new liner is properly installed and fully cured.

Data Upload: All operational data and images are automatically uploaded to the cloud, providing a comprehensive record of the rehabilitation process.